Obtain Pattern Approval for weights, Measures and weighing or Measuring Instruments.

Pattern Approval for weights, Measures and weighing or Measuring Instruments.

The Measurement Units, Standards and Services Department holds the authority to approve weights, measures and weighing or measuring instruments that are manufactured or imported according to OIML standards.

However, the Measurement Units, Standards and Services Department selects and applies only some of the OIML standards that are appropriate for Sri Lanka.

Eligibility

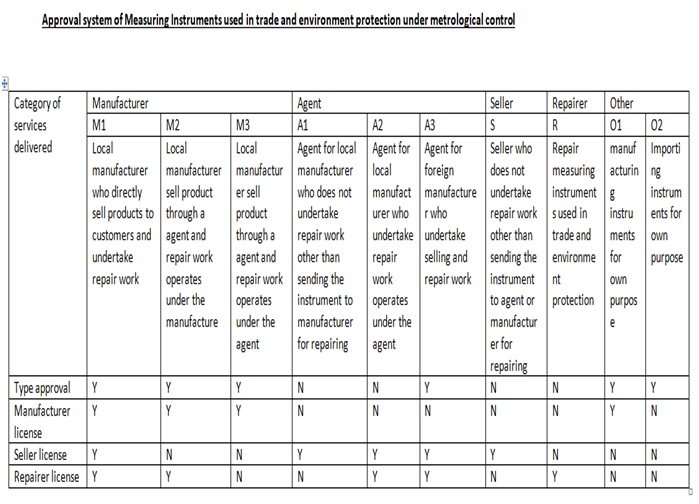

A manufacturer or seller who prefers to obtain this service should be in the following criteria.

- Applicant must possess a repair license

- In the case of approving an imported instrument, the company or individual that sells the instrument should be identified as an authorized dealer with the manufacturers company.

Note : If the applicant does not have a repair license he/she must apply for one from the Department of Measurement Units, Standards and Services before repairing a stamped measuring instrument.

Approval Procedure for Measuring Instruments / Device

General Metrological and Legal Requirements for legal control of testing equipment

Measuring equipment shall be included all required characteristics required for legal controlled of measurements of measuring equipment for pattern approval, initial verification and periodic verification by Measurement Units, Standards and Services Department (MUSSD) as follows;

- Physical access to internal components, circuitry and mechanical parts critical to affect to measurements shall be physically sealable.

- For calibration and change of parameters effected to measurement results shall secure by a physical jumper or switch inside the sealable unit according to 1.1 and could not be accessed without breaking the seal or include a non-resettable event counter and event log in software/Firmware including records of calibrations, changing calibration parameters, Number of times changed calibration parameters, date time stamp in YYYY-MM-DD hh:mm:ss format in Sri Lanka Standard Time and other critical parameters like Fare rates, Corrective factors, constant etc… which shall be readable without any password.

- Measuring equipment shall able to calibrate from traceable measurement standard for the required range and accuracy and shall have menu or display to check calibration parameters and calibration dates. If calibration expired measuring equipment shall be inhibited its measuring operation and clearly indicate its status.

- Intermediate checks shall be conducted 3 months’ intervals with traceable measurement standards to verify the annual calibration/verification status and adequate traceable measurement standards available for above purpose. Proper maintenance schedule shall be followed and technical staff, equipment, tools and materials shall be available for maintenance work. All above details shall be properly documented.

- Shall have a method to identify the equipment operator by a proper method (Passwords, RF cards, Fingerprints etc..) when the operator intervention is significant for final measurement results, equipment unique identification (Serial number etc..) and calibration/verification date. Above information shall be available with the final measurement results.

- Shall have a method for verification of calibrated parameters and other critical parameters (Fare rates, Corrective factors, constant etc…) with a measurement standard and shall be included a convenient audit menu/display for above purpose.

- Software of the measuring instrument can be operated on a general operating system (OS), but access to other functions shall not allow any means without passing through the software dedicated for the measuring instrument. Software shall have all the characteristics for legal control. Identification of the software with its version numbers/revision numbers shall be available. Any alterations to the approved software shall be restricted by adequate physical/ software means.

Applications and Approved Weighing & Measuring List